- M-LOK Handguards

- M-LOK Accessories

- KeyMod Accessories

- Barrels

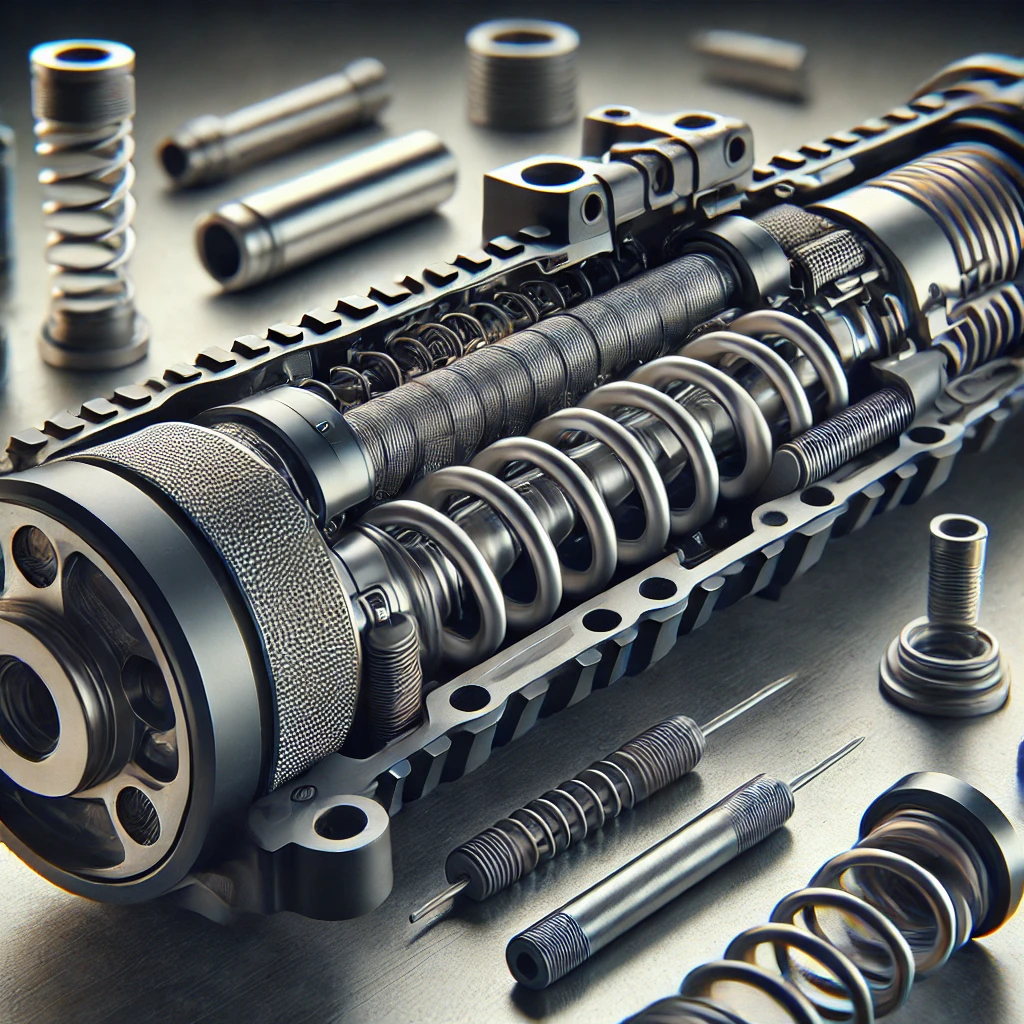

- Bolt Carrier Groups

- Charging Handles

- Complete Kits

- Gas Blocks

- Gas Tubes

- Iron Sights

- Lower Parts

- Mags

- Muzzle Devices

- Pistol Stock Sets

- Pistol Grips

- Pistol Accessories

- Slings

- Stock Components

- Stocks

- Stock Sets

- Stock Sets With Matching Upper

- Tools

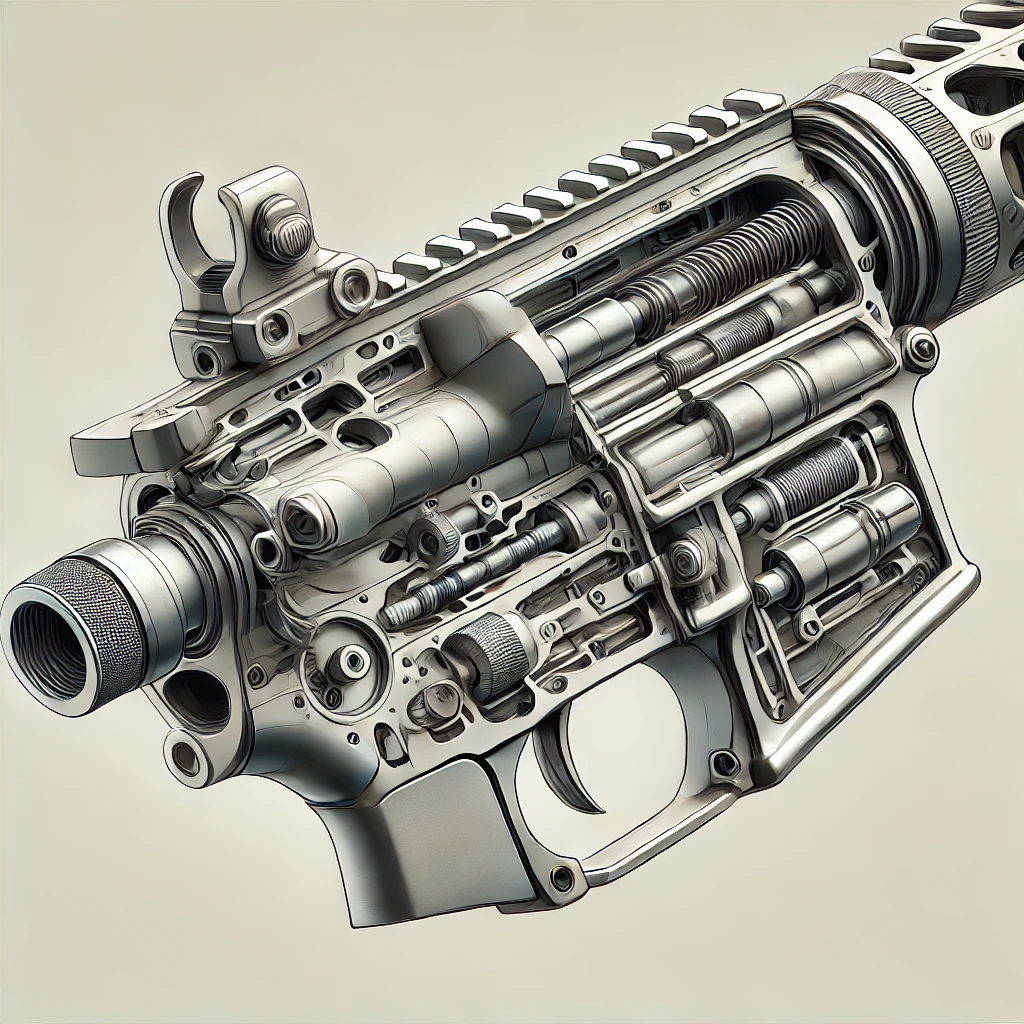

- Upper Kits

- Upper Parts

- Upper Receivers

- Upper Sets

- Vertical Grips

Top 5 Tactical Trends in AR-15 Accessories in Year 2025

Top AR-15 trends 2025: lightweight gear, advanced optics 🚀🔫